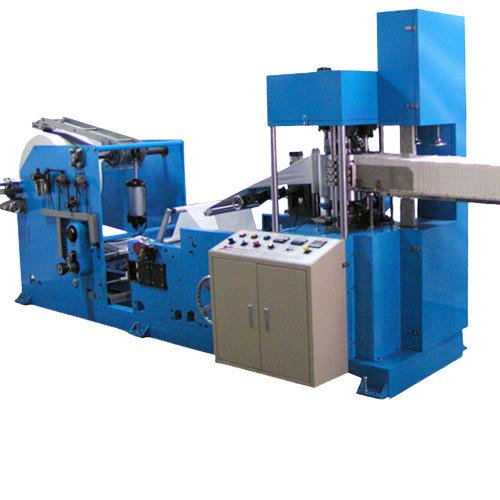

A tissue paper making machine is a large and complex piece of machinery that is used to produce tissue paper from paper pulp. The machine typically consists of the following components:

- A headbox: This is where the paper pulp is mixed with water and distributed evenly across a wire mesh.

- A forming section: This is where the paper web is formed as the water drains out.

- A press section: This is where the paper web is pressed to remove more water.

- A drying section: This is where the paper web is dried using hot air or steam.

- A winding section: This is where the paper web is wound onto a roll.

- A cutting and packing section: This is where the paper is cut to size and packaged.

The tissue paper making machine is a continuous process, meaning that the paper web is produced continuously. The speed of the machine can vary depending on the desired thickness of the tissue paper.

Here is a more detailed description of the steps involved in tissue paper making:

- The paper pulp is mixed with water in the headbox. The amount of water used will determine the thickness of the tissue paper.

- The paper pulp is distributed evenly across a wire mesh in the forming section. The wire mesh is vibrated to help remove water from the paper web.

- The paper web passes through the press section, where it is pressed to remove more water.

- The paper web passes through the drying section, where it is dried using hot air or steam. The drying time will depend on the desired thickness of the tissue paper.

- The paper web passes through the winding section, where it is wound onto a roll.

- The paper is cut to size and packaged in the cutting and packing section.

Tissue paper making machines can be either manual or automatic. Manual machines are less expensive, but they require more labor. Automatic machines are more expensive, but they are more efficient and produce a higher quality of tissue paper.

The size and capacity of a tissue paper making machine will vary depending on the desired production volume. Smaller machines can produce a few thousand sheets per hour, while larger machines can produce hundreds of thousands of sheets per hour.

Tissue paper making machines are used in a variety of industries, including:

- Toilet paper manufacturing

- Facial tissue manufacturing

- Napkin manufacturing

- Paper towel manufacturing

- Industrial wiping tissue manufacturing

Tissue paper making machines are an essential part of the paper industry. They are used to produce a wide variety of tissue products that are used in homes, businesses, and industries around the world.